Cyclic Corrosion Chamber Modes of Operation

Ascott’s Cyclic Corrosion Chamber advanced control system gives great flexibility. The customer can comply to a wide range of different cyclic corrosion test specifications, due to the extensive range of accessories that can be added to a chamber. As standard they come with the ability to create 6 distinct functions to create the most common corrosive environment:

Ascott’s Cyclic Corrosion Chamber advanced control system gives great flexibility. The customer can comply to a wide range of different cyclic corrosion test specifications, due to the extensive range of accessories that can be added to a chamber. As standard they come with the ability to create 6 distinct functions to create the most common corrosive environment:

- Salt Spray Fog

- Condensation humidity (wetting)

- Forced Air drying

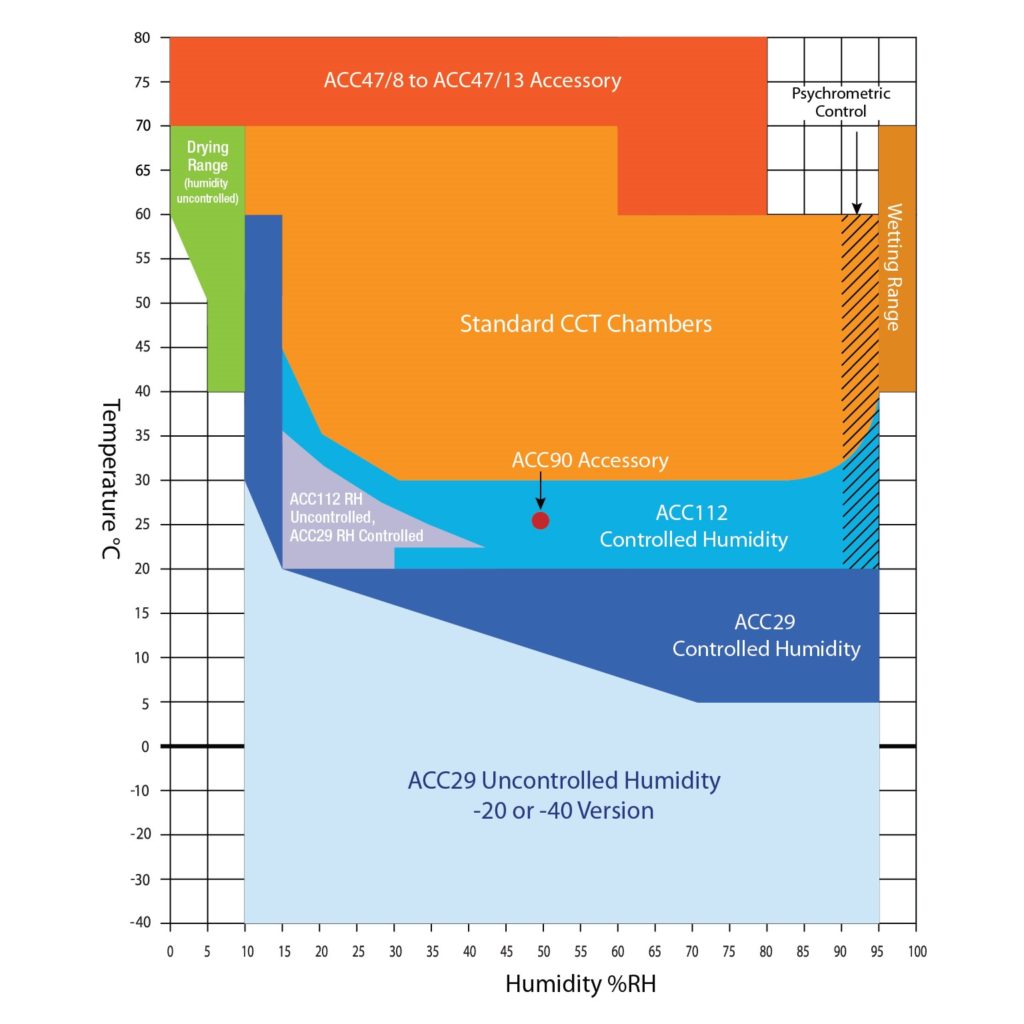

- Controlled humidity (see adjacent graph)

- Ambient Drying

- Temperature Only Control

All may be programmed, using the intuitive full Colour 7” HD Touchscreen interface, to occur in any sequence and can be repeated automatically.

Standard control features for the Ascott Cyclic Corrosion chamber:

-

-

- 7’’ ‘touch’ activated screen, with a 480p (0.38 megapixel) high resolution display, and a ‘menu’ driven icon based commands, available in multiple languages for ease of understanding and use.

- Temperature and Humidity monitoring in SCADA using OPC-UA. (Open Platform Communications United Architecture)

- Large capacity memory, allowing for extensive customer programs to be stored, 254 main programs of up to 200 steps, 100 sub programmes and 254 single line programs.

RJ45 communications port for connection to a local area network (LAN) for logging and remote programming via a computer running optional Ascott software (ACC121).

RJ45 communications port for connection to a local area network (LAN) for logging and remote programming via a computer running optional Ascott software (ACC121).- A real-time, user configurable ‘clock’ to enable different test samples to have their exposure time monitored separately, with alarms to warn when preset test times have been completed.

- On/Off function with Temperature control for intermittent salt spray applications.

- Ambient drying function to open/close the canopy during a test, exposing the samples to ambient conditions in the room.

-