CorroFlex – Key Features

Ascott CorroFlex Chambers

Flexible Size Corrosion Test Chambers

In response to customer demand for larger test chambers to test large samples, in a wide variety of shapes, sizes and weights, Ascott are pleased to introduce their latest range of CorroFlex flexible size corrosion test chambers.

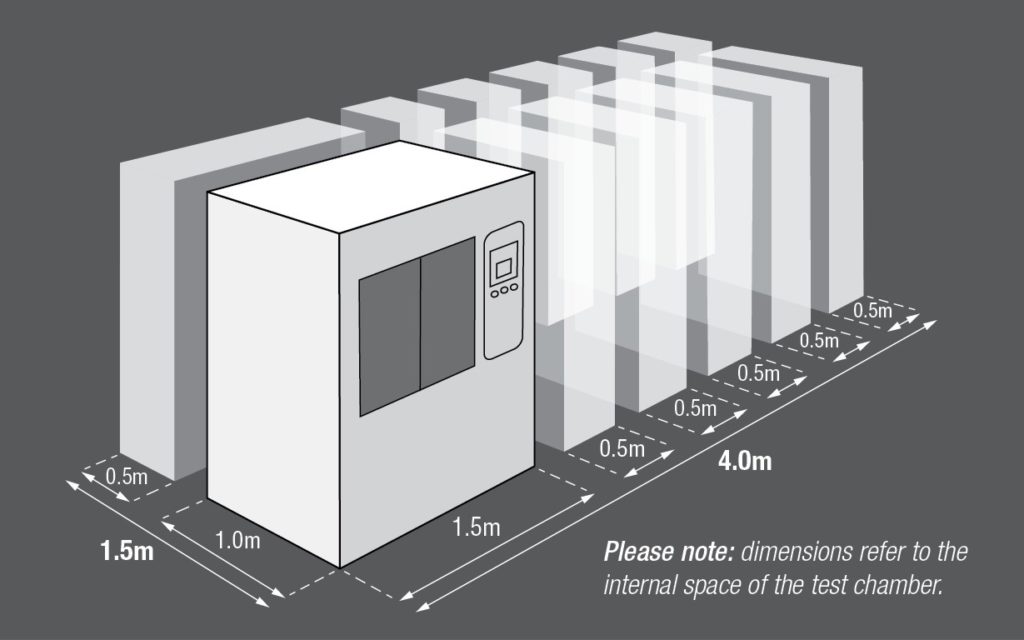

These chambers all feature the convenience of a front loading door, which fully opens and closes at the push of a button, giving unimpeded access to the chamber interior. The door slides up to close and down to open, minimising the floor space required when installed. CorroFlex corrosion test chambers offer the user flexibility in specifying the perfect size of chamber to suit their application. The width and depth dimensions are variable and can be selected in 0.5m increments.

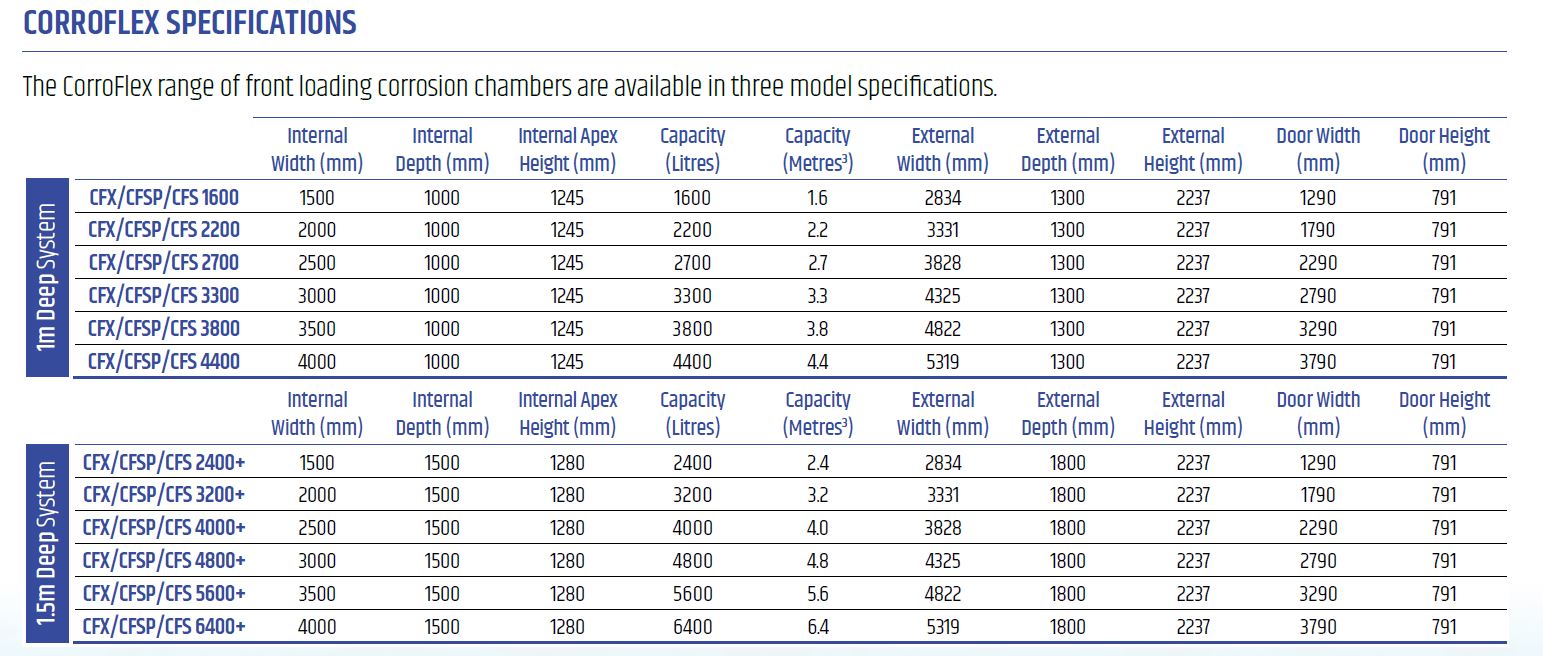

The CorroFlex range of front loading corrosion chambers are available in three model specifications:

CFS: CFS models are salt spray only test chambers and can perform single temperature, continuous salt spray tests in accordance with international standards such as: ASTM B117, ISO 9227, JIS Z 2371 and many more.

CFSP: CFSP models are Premium salt spray

chambers and can perform the same basic

salt spray tests as Standard models, but in

addition are equipped with extra features

enable them to undertake ‘modified’ tests

such as ASTM G85. Here conventional salt

spray is usually combined with one other

climate, in a two-part cycle.

CFX: CFX models are cyclic corrosion chambers and can be programmed to create any of 4 distinct climates: salt spray, controlled humidity, air drying and condensation humidity. These climates can be programmed to occur in any sequence for any period of time and repeat automatically. The CFX models also have the ability to automatically open and close their door as part of the test cycle if required, exposing the samples to laboratory ambient conditions as well.

Click here for a link to the brochure – CorroFlex Brochure

CFS Key Features:

• True colour 3.5’’ Touch-screen controller interface, for ease of programming and control, with graphical display of temperature.

• Centrally located viewing window/s for good visual access to chamber interior and test samples when door closed.

• Centrally located viewing window/s for good visual access to chamber interior and test samples when door closed.

• Timed canopy lock and purge of the chamber interior with fresh air after testing and before the chamber is opened, preventing corrosive salt fog escaping.

• Peristaltic pumping system for precise control and delivery of the salt solution.• Chamber heated by externally mounted heater mats, protecting them against damage from the corrosive climate inside the chamber, and ensuring uniform heat distribution inside the chamber.

CFSP Key Features:

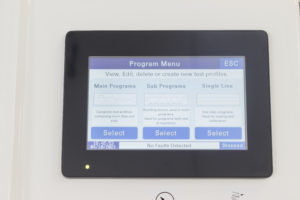

- 480p (0.38 megapixel) high resolution icon based interface available in multiple

languages for ease of understanding and use.

languages for ease of understanding and use.- Large capacity memory, allowing for extensive customer programs to be stored, 254 main programs of up to 200 steps, 100 sub programmes and 254 single line programs.

- True colour, 7’’ wide screen WVGA Screen user control interface, using the latest version of our highly intuitive operating software.

- Integrated immersion heater to create condensation humidity, for testing to a wider range of ‘modified’ salt spray tests.

- Temperature and Humidity monitoring in SCADA using OPC-UA.

- RJ45 communications port enabling the chamber to be wire or wirelessly connected to a local area network (LAN) for logging and remote programming via a computer running optional software

CFX Key Features:

CFX Models have the same features as CFSP models plus:

- CFX combines salt spray with other environmental conditions such as controlled humidity, air drying and condensation humidity modes.:

- Salt Spray Mode

- Temperature range – Adjustable from ambient to +60°C/+140°F.

Salt spray fall-out rates – Adjustable from 0.5 to 2 ml per 80c m2 per hour.*

- Temperature range – Adjustable from ambient to +60°C/+140°F.

- Wetting Mode

- Temperature range – Adjustable from ambient to +70°C/+158°F.

Humidity range – Fixed at 95% – 100% RH.

- Temperature range – Adjustable from ambient to +70°C/+158°F.

- Forced Air Drying Mode

- Temperature range – Adjustable from ambient to +70°C/+158°F.

- Controlled Humidity Mode Temperature/humidity range – Details on request.

- Controlled Temperature Only Mode

- Adjustable from ambient to +50°C/+122°F.

- Ambient Air Drying Mode

- Chamber canopy can be programmed to slide open and close at any point

during a test.

- Chamber canopy can be programmed to slide open and close at any point

- Salt Spray Mode

Technical Specification

For further information contact us on the form below, alternatively, to speak with one of our sales representatives call us on +44 (0) 1827 318040