Atmosfär Premium Modes of Operation

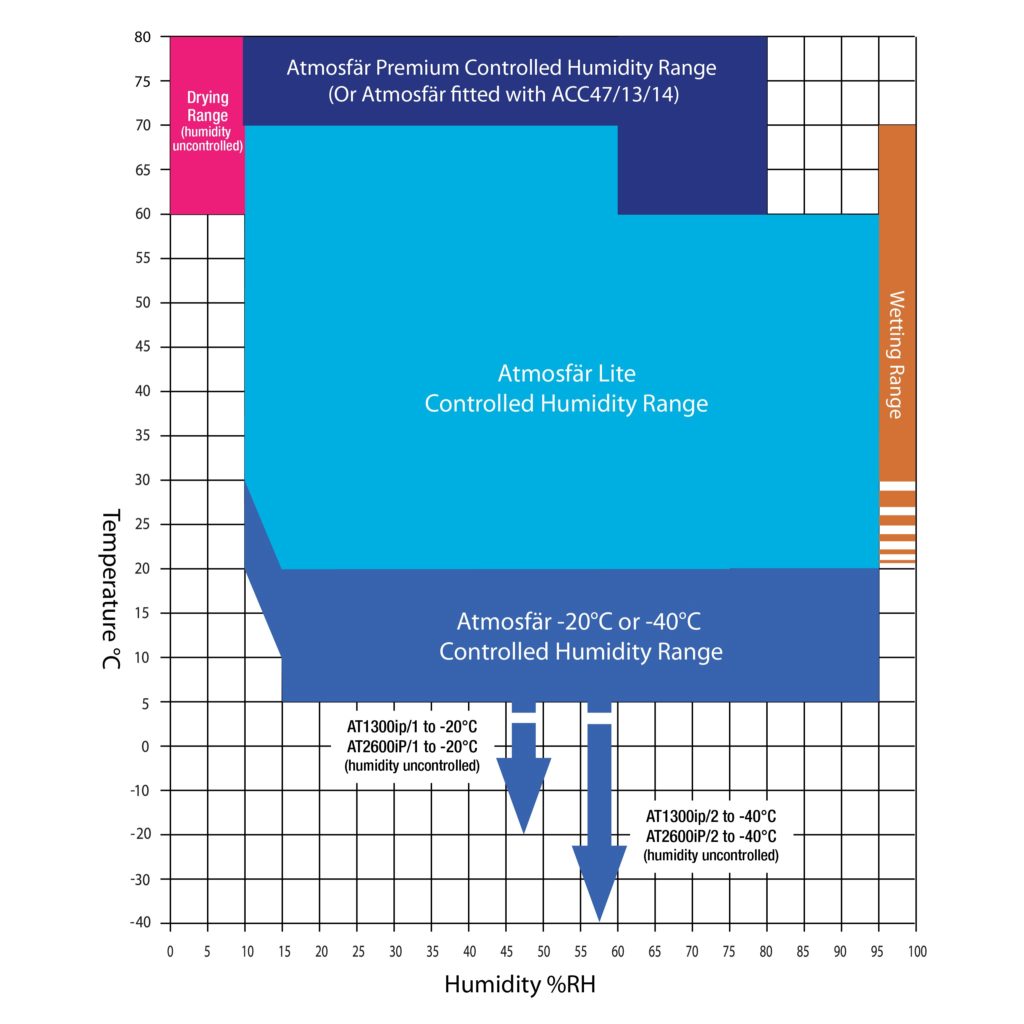

AtmosfärPremium Modes of Operation Performance Graph

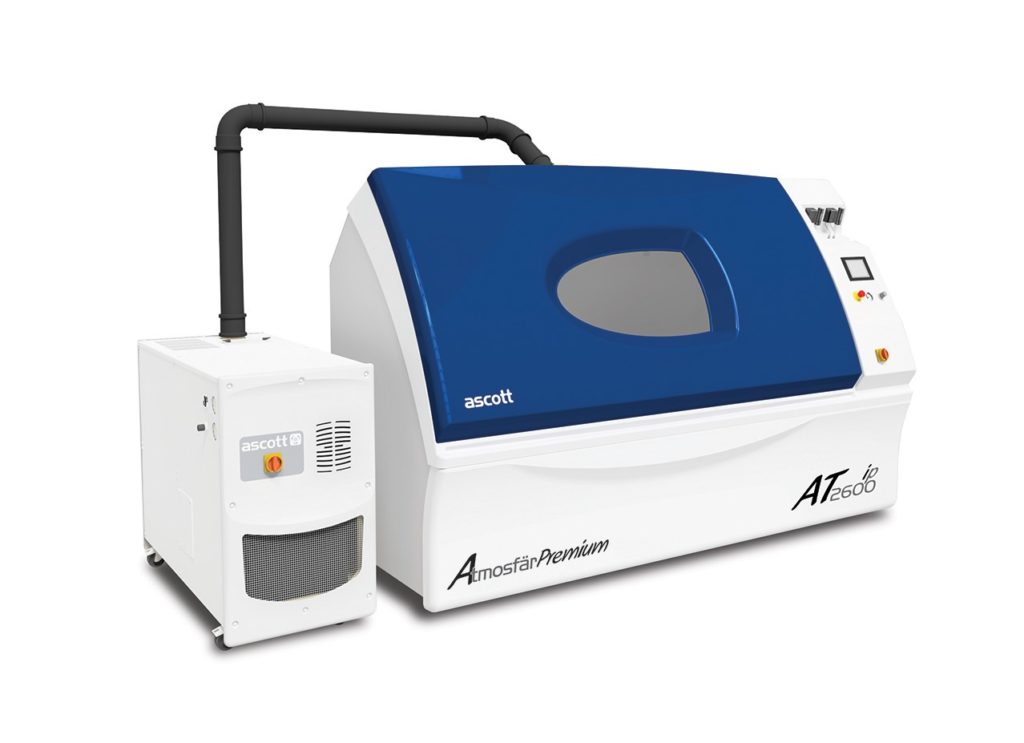

The AtmosfärPremium control system has the widest temperature and humidity envelope in the Ascott chamber range. Not only can the chamber comply with a large number of different less demanding Cyclic and Salt Spray test standard specifications such as, ASTM, Renault’s ECC1, JASO & VDA but can also comply with environmental temperature & humidity testing required by Volkswagen P-VW-1200 & P-VW 1209. Making the AtmosfärPremium chamber truly without equal in the world of corrosion testing.

Our range of standard cyclic chambers come with the ability to create 6 distinct functions to create the most common corrosive environments:

- Salt Spray Fog

- Condensation Humidity (wetting)

- Forced Air Drying

- Controlled Humidity

- Ambient Drying

- Temperature Only Control

All may be programmed, using the intuitive 7” full colour HD Touchscreen interface, to occur in any sequence for any period of time, and can be repeated automatically.

In addition to the above, the Atmosfär range also includes:

- A range of 3 Sub cooling units

- Lite Version +20°C / 68°F to +80° / 176°F

- Sub Zero version -20°C / -4°F to +80° / 176°F

- Sub Zero version -40°C / -40°F to +80° / 176°F

- Now also available with CO2 Cooling according to EU F-GAS regulation 2024/573

Oscillating Vertical spray down swaying bar with uniform fallout.

Oscillating Vertical spray down swaying bar with uniform fallout.

- Psychrometric control of humidity.

- Uniform airflow from above.

- Excellent temperature uniformity.

The AtmosfärPremium range also incorporates

- Increased temperature and humidity control to +80°C / 176°F and 80%RH

- Rapid ramping of temperature and humidity transitions

- Chamber logging software included

- A 110mm Entry Port to enable the connection of external monitoring/driving equipment to the load under test.

- Dual atomizer salt spray system, which increases the fallout rates up to 5.5ml per 80cm2 per hour for, VDA 233-102, RNES-G-0005, ECC1 and SAE J tests

- Increased humidity generation with the addition of chamber wall wash facility

Typical modes and transitions that can be achieved:

- 35°C Salt Spray (100%RH) to 70°C Air Drying < 30 mins ~(Required by Hyundai CCT-B)

- 70°C Air drying to 50°C >95% RH < 20mins ~(Required by Hyundai CCT-B)

- 50°C >95% RH to Salt Spray 35°C (100%RH) < 30 mins (Required by Hyundai CCT-B, CCT 1, CCT 2, JASO M609, JASO M610)

- 60°C Air Drying to -20° C < 60 mins

- 80°C / 80% RH Controlled Humidity to -40°C Freezing in 120 mins (Required by VW PV1200 & VW PV1209)

Extra scope for other Test Standard requirements can also be fulfilled because of our wide range of optional accessories that are available which further extend the number of climates and conditions that can be created. See below for standard operation as well as just a few of the additional accessories that expands the range.

Explore the range of accessories

Learn more about the key features of Atmosfär Chambers.