List of Ascott Optional Accessories

All Ascott test chambers are supplied complete and ready to run. Optional accessories may not therefore be necessary, but some may be considered desirable. Our team are happy to answer any questions you may have. Please contact us on +44 (0) 1827 318040 or email sales@ascott-analytical.com

- Additional Chamber Fittings

- Automation Accessories

- Data Measurement & Recording

- External Service Utilities

- Optional Testing Facilities

- Service & Spares

| Optional Accessory | Ref. | Description | Factory Fit Only | |

|---|---|---|---|---|

| Kit for Renault ECC-1 / D17-2028 compliance | ACC01 | A comprehensive kit of all necessary accessories to equip an Ascott chamber for compliance with Renault D17-2028 & RNES-G-005 which is commonly known as ECC-1. The kit includes ACC42 Wall Wash system, ACC47 Rapid Transition Time Heater Blower system, ACC82 Insulated Window Cover, ACC102 Salt Solution Consumption Indicator, ACC108 Fallout Measuring Kit and an increased Salt Fog Fallout system to achieve the required fallout The Ascott ECC1 Kit has been Renault as compliant. Not suitable for use with ACC46 So2 System. Note kit supplied as standard on Atmosfar Premium models | |

| Salt Solution Resevoir (80 Litres) | ACC59/1 | An 80 Litre (21 US gal) capacity salt solution reservoir, with a graduated scale in litres, a hinging lid for ease of filling and cleaning and mounted on castors for mobility. External Dimensions: 460mm/18″ (w) x 620 mm/24″ (d) x 675mm/26″ (h) | |

| Salt Solution Reservoir (115 Litres) | ACC59/5 | A 115 Litre (30US gal) capacity salt solution reservoir, with a graduated scale in litres, a hinging lid for ease of filling and cleaning and mounted on castors for mobility. External Dimensions: 560mm (w) x 620 mm (d) x 675mm (h) | |

| Salt Solution Resevoir (160 Litres) | ACC59/9 | A 160 Litre (42.2 US Gal) capacity salt solution reservoir, with a graduated scale in litres, a hinging lid for ease of filling and cleaning and mounted on castors for mobility. External Dimensions: 840mm (w) x 500mm (d) x 790mm (h) | |

| Air Compressor (large) | ACC04/2 | A large free standing compressor, to provide a continuous supply of clean, dry and oil free compressed air, to enable the chamber to function without requiring connection to a local compressed air supply. Electrical supply: 220-240VAC single phase, 50Hz | |

| Guardian Angel System - Standard LED Version | ACC05/1 | Modular traffic light alarm system fitted to the top of chambers, to provide visual notification of chamber status. Only available for Premium chambers (iP designations) | |

| Guardian Angel System - LED Version, with USB Connectivity | ACC05/2 | Modular traffic light alarm system fitted to the top of chambers, to provide visual notification of chamber status, with USB connectivity for remote monitoring. Only available for Premium chambers (iP designations) | |

| Guardian Angel System - LED Version, with Ethernet Connectivity | ACC05/3 | Modular traffic light alarm system fitted to the top of chambers, to provide visual notification of chamber status, with Ethernet connectivity for remote monitoring. Only available for Premium chambers (iP designations) | |

| Guardian Angel System - USB add on only | ACC05/4 | Retrofit add on for Guardian Angel, allows addition of USB connectivity for remote monitoring. Only available for Premium chambers (iP designations) | |

| Guardian Angel System - Ethernet add on only | ACC05/5 | Retrofit add on for Guardian Angel, allows addition of Ethernet connectivity for remote monitoring. Only available for Premium chambers (iP designations) | |

| Water Deioniser System (Small) | ACC06/1 | To provide water of suitable purity for topping up a salt spray/cyclic corrosion chamber air saturator, and for making up salt solution to be sprayed. Requires connection to a continuous mains water supply of maximum pressure 5.0 bar. This system comprises of a regenerable cylinder deioniser and an electronic conductivity indicator. Must be regenerated or replaced when exhausted. | |

| Water Deioniser System (Medium) | ACC06/2 | To provide water of suitable purity for topping up a salt spray/cyclic corrosion chamber air saturator, and for making up salt solution to be sprayed. Requires connection to a continuous mains water supply of maximum pressure 5.0 bar. This system comprises of a regenerable cylinder deioniser and an electronic conductivity indicator. Must be regenerated or replaced when exhausted. | |

| Water Deioniser System (Large) | ACC06/3 | To provide water of suitable purity for topping up a salt spray/cyclic corrosion chamber air saturator, and for making up salt solution to be sprayed. Requires connection to a continuous mains water supply of maximum pressure 5.0 bar. This system comprises of a regenerable cylinder deioniser and an electronic conductivity indicator. Must be regenerated or replaced when exhausted. | |

| 35mm Entry Port | ACC10/1 | Sealable chamber entry port of 35mm (1.27″) through the chamber’s left hand wall to enable the connection of external monitoring/driving equipment. Note: not suitable for use with option ACC46. | |

| 110mm Entry Port | ACC10/2 | Sealable chamber entry port of 110mm (4.33″) through the chamber’s left hand wall to enable the connection of external monitoring/driving equipment. Note: not suitable for use with option ACC46 or 120Ltr chambers | |

| Hand-held salinity refractometer | ACC100 | A salinity refractometer optimized to give a direct reading of percentage sodium chloride in the range 0 to 28%, with automatic temperature compensation. A single drop of the salt solution to be measured is placed on the viewing window, using the pipette supplied, and its salinity read against a high contrast scale, graduated in % sodium chloride, to give an accurate reading. | |

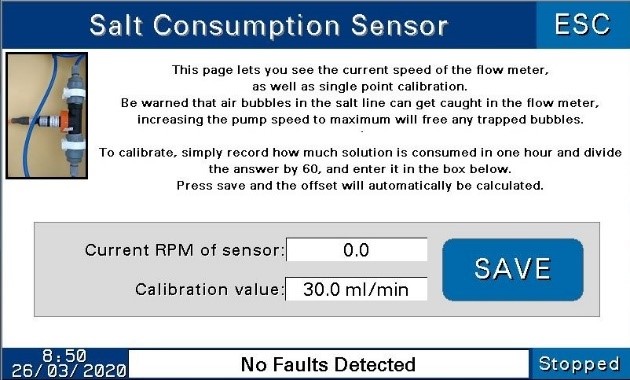

| Salt Solution Consumption Sensor | ACC102 | Electronic liquid flow sensor mounted inside the chamber and sensor situated in-line between the salt solution reservoir and the salt spray atomizer. The sensor measures the flow of salt solution from the reservoir to the atomizer. The output from the is displayed digitally at the chamber display as instantaneous consumption in ml per min and total consumption in ml. Designed for use where a high salt solution flow rate is required and where that flow rate should be displayed electronically, such as Renault D17 2028. This has collection rates that equate to 4-6ml/80cm²/hr. This system may not work effectively at collection rates below this. Only available for Premium chambers (iP designations). | |

| Fallout Measuring Kit | ACC108 | Comprises of 4 x 100ml measuring cylinders and 4 x 100mm funnels, for manually collecting and measuring salt spray fall-out inside a chamber, during salt spray testing. | |

| Hand held pH meter | ACC11 | Digital pH meter, for measuring the pH of salt solution fallout over range 0-14 pH with a resolution of 0.01 pH. Supplied complete with buffers for calibration. | |

| Vertically Operating Canopy | ACC110 | Special design of canopy to allow it to open to a vertical position to enable access from above (e.g. by hoist) for large and/or heavy test samples. *Exact part number dependent on chamber size. | |

| Midi Dehumidification Unit | ACC112 | A mid-size, air conditioning unit, to enable controlled ‘ambient’ climates to be created within a CCT chamber. *Exact part number dependent on chamber size. Note: all versions of ACC112 require the chamber to be pre-equipped with option ACC112/INT/**** | |

| Interface for ACC112 | ACC112/INT | Pre-equips a CCT chamber with everything needed to connect it to an ACC112 midi dehumidification unit (available separately). The fitting of this interface enables the midi dehumidification unit to be procured at the same time as the chamber, or later if required. *Exact part number dependent on chamber size. | |

| 12 Month Consumables Kit for Cyclic Chambers | ACC57/2 | A kit of consumables sufficient for operating an Ascott Atmosfär, Kesternich, Cyclic or Salt Spray Premium chamber for up to 1 year. Includes Salt Filters for Atomiser, Silicone tubing, Humidity Prove Filter Cap with O Ring & Air Filter Note: A consumables spares kit is supplied as standard with every new chamber. | |

| 36 Month Servive & Spares Kit | ACC12/2 | An initial kit of spare parts for servicing and maintaining a chamber for up to 3 years from its first use. | |

| 72 Month Service & Spares Kit | ACC12/3 | A comprehensive kit for servicing and maintaining a chamber for up to 6 years from its first use, or its last service. | |

| Data Logging Software | ACC121 | This software allows logging of chamber variables and editing of chamber programs. It is uses a graphics based display which mimics and improves on the chamber interface. It can be loaded on Workstations or Laptops with Operating systems of Windows 10, Windows 8 Professional, Windows 7 Professional, Windows 2000 (SP4+), Windows XP Professional (SP3+). It also requires the following minimum hardware requirements – 1 GHz Processor minimum Processor, 256 MB RAM, video 1280 x 1024 (high colour 16 bit) and it is advised 2GB Hard Disk Space for data. The software communicates via an Ethernet network adaptor from chamber to PC / Laptop. The Workstation / Laptop also require a USB port to load the software and to accommodate the Dongle that is needed to run this software. Network must also be suitable as it will only work across a network on Class C subnet masks/ IP addresses – please liaise with your IT departments to confirm this or contact Ascott for further information. Only available for Premium chambers (iP designations). | |

| Mesh Racking | ACC15 | Mesh type racking with an aperture of 30mm for testing small component parts. Locates on either the upper or lower level supports provided as standard inside the chamber, and removable if required. This product is available in a variety of sizes to suit different capacity chambers. | |

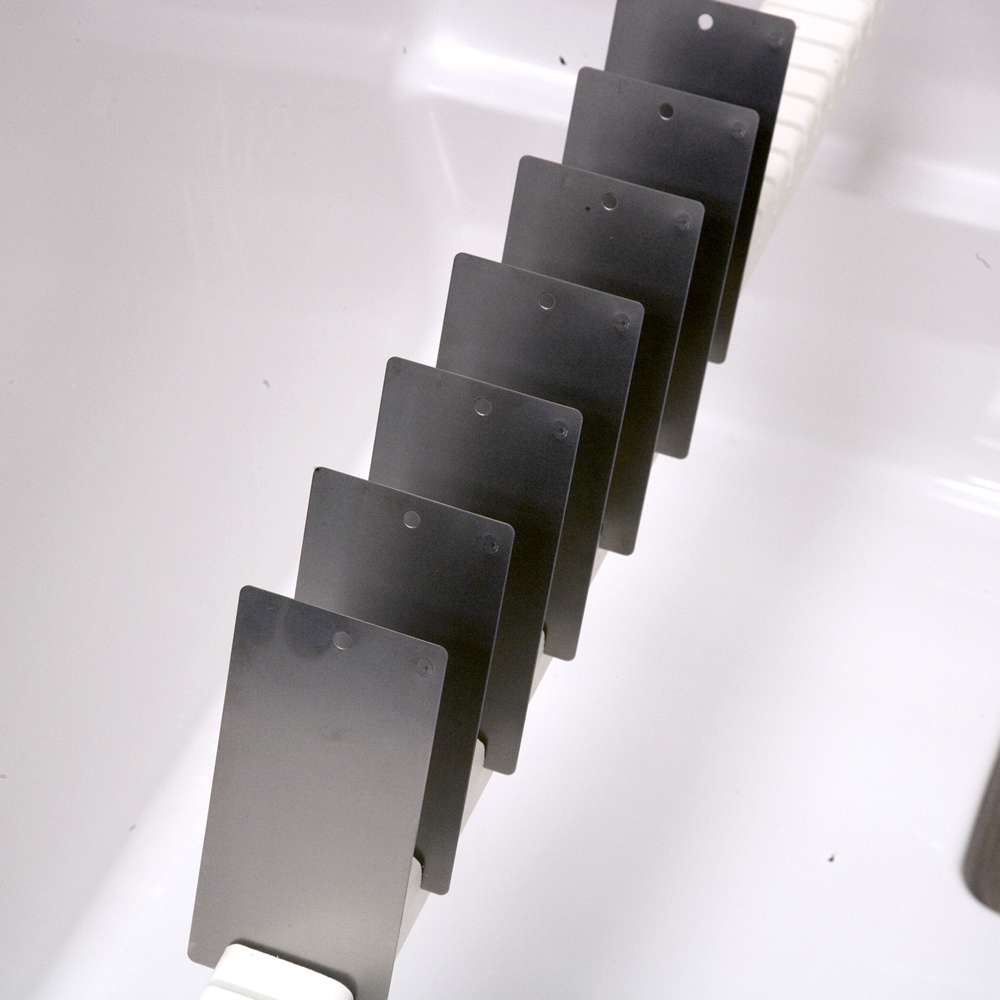

| Slotted Sample Racks | ACC16 | Removable slotted type sample rack for testing panels/coupons. Each slot is 3mm/1/8” wide and angled at 15 degrees from vertical. Such racks are supplied as standard, unless otherwise specified. Wider slots and/or different angles are available on request. *Exact part number dependent on chamber size. | |

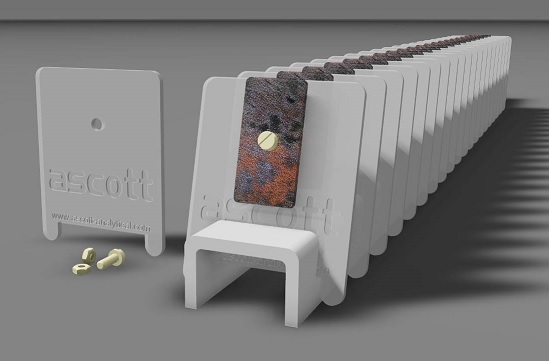

| General Motors Test Plate Kit | ACC16/6 | A kit of 10 specially designed Polycarbonate test plate holders and nylon fixings, as pictured, for mounting General Motors test plates in accordance with the requirements of GMW14872 – in an existing Ascott slotted sample rack, ref ACC16. | |

| Variable Sample Racks | ACC14 | Slotted sample racks for testing coupons on which the slot width and slot angle can be varied. | |

| Rod Sample Racks | ACC17 | Removable rod type sample rack for suspending small test samples hung beneath, or for supporting larger test samples placed on top of these racks. *Exact part number dependent on chamber size. | |

| Spiked Sample Racks | ACC18 | Removable spiked type sample rack for suspending test samples from the 10mm/0.4″ diameter x 55mm/2″ long spikes, equally spaced, and protruding from opposite sides. *Exact part number dependent on chamber size. | |

| Reinforced False Floor | ACC19 | Removable reinforced false floor, providing a horizontal platform over the chamber base for supporting large/heavy test samples. *Exact part number dependent on chamber size. | |

| Waste Water Trough & Pump | ACC20 | Where a floor level drain connection is unavailable this option provides a holding tank into which the chamber drain outlet is terminated. When full, waste water is automatically pumped to an existing remote drain/effluent tank, up to 10m/32ft horizontally & 3m/10ft vertically from the chamber. Note: not suitable for use with option ACC46. | |

| Additional Atomisers | ACC25 | Additional salt spray atomiser(s) and associated pump(s) to generate the higher fall-out rates (2.0 to 5.5ml/80cm²/hour) required during the salt spray phase of the VDA 233-102, Renault D17 2028 (ECC1), SAEJ 2334 and RNES-G-0005. Note: option ACC25 is not required if option ACC01 is ordered and is fitted as standard to AT Premium chambers | |

| Interior Lighting | ACC26 | Illuminates the chamber interior when a control panel push-button is pressed. *Exact part number dependent on chamber size. | |

| Hand Held Temperature & Humidity Probe | ACC28 | Precision hand-held thermo-hygrometer for independently checking the chamber temperature and humidity. Includes a special salt resistant measuring probe mounted on an extension cable. Range: -40 to +85°C & 0 to 100%RH. Requires any size entry port (see option ACC10) to access the chamber interior. | |

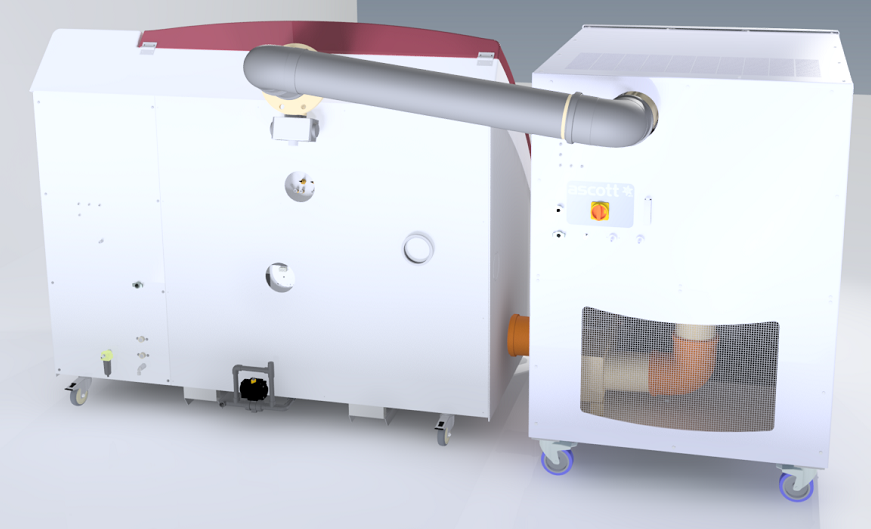

| Refrigeration & Humidity Control Unit | ACC29 | A separate free standing air temperature and humidity conditioning unit (ATCU), capable of refrigerating a cyclic chamber to -20°C or -40°C *Exact part number dependent on chamber size. Note: all versions of ACC29 require the chamber to be pre-equipped with option: ACC29/INT/**** | |

| Air Conditioner Interface | ACC29/INT | Pre-equips an Ascott Cyclic Corrosion Chamber with everything needed to connect it to an ACC29 air conditioning unit (available separately) The fitting of this interface enables the air conditioning unit to be procured at the same time as the chamber, or later if required. *Exact part number dependent on chamber size. Note: not suitable for use with option ACC46. | |

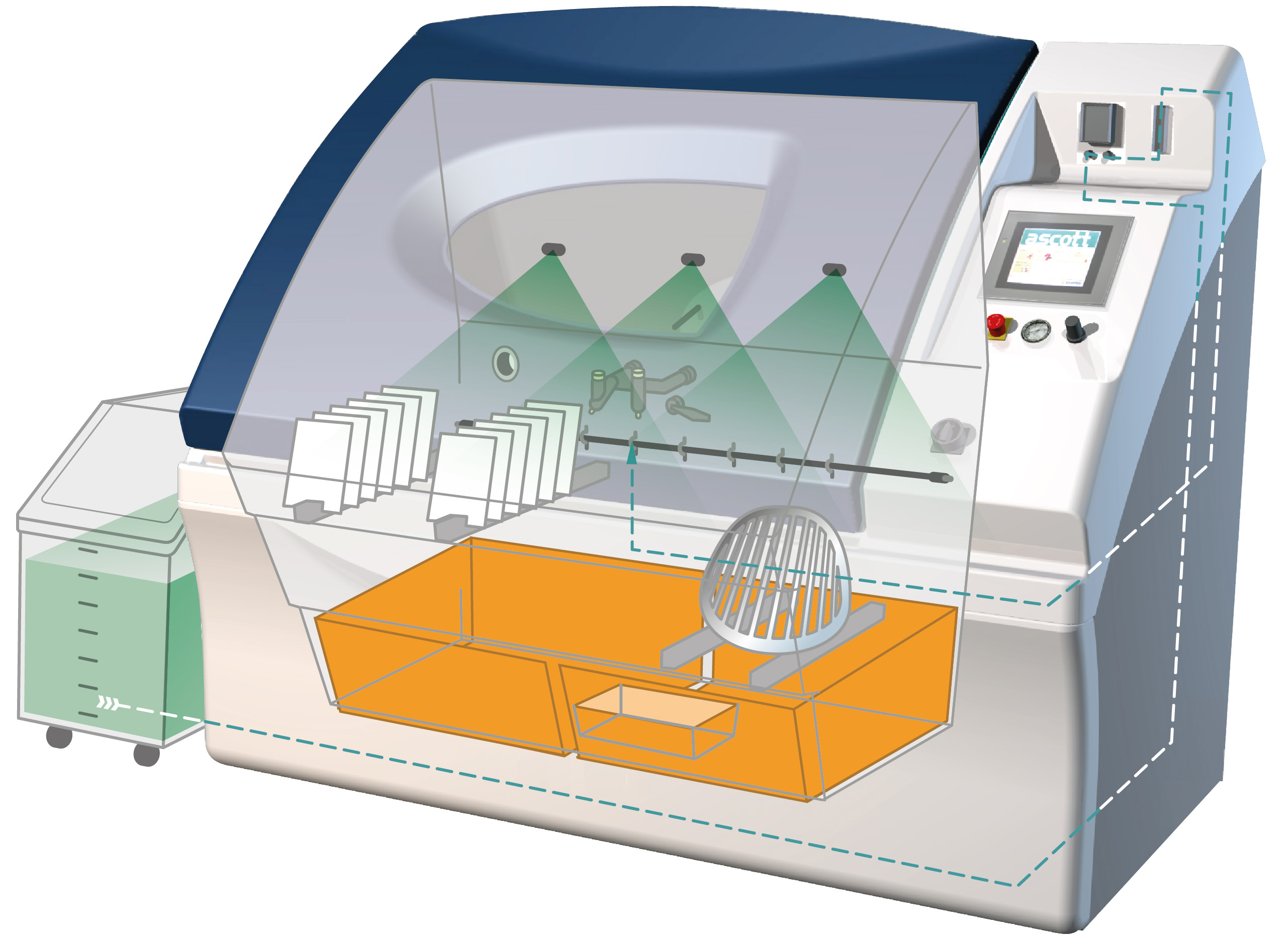

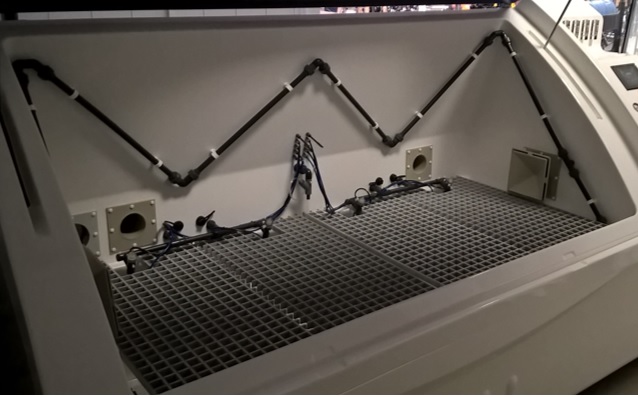

| Salt Spray (Vertically Down) | ACC30 | High level, multiple spray nozzles which spray salt water directly down onto the samples under test. Spray time and duration are both user programmable. A separate holding tank holds salt water at ambient temperature. Required by SAEJ2334 and some GM tests. *Exact part number dependent on chamber size. | |

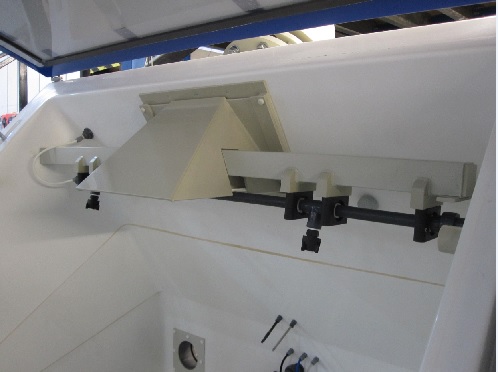

| Oscillating Spray Bar | ACC31 | Overhead oscillating spray bar with magnetic drive mechanism. *Exact part number dependent on chamber size. Note:Can only be fitted to CC1300iP and CC2600iP Chambers | |

| Water Fog Humidity Generation | ACC32 | Provides high humidity conditions (95 -100% RH) by spraying water as a fog. Includes an additional reservoir for water, fog atomizer(s) and associated pumping equipment. *Exact part number dependent on chamber size. | |

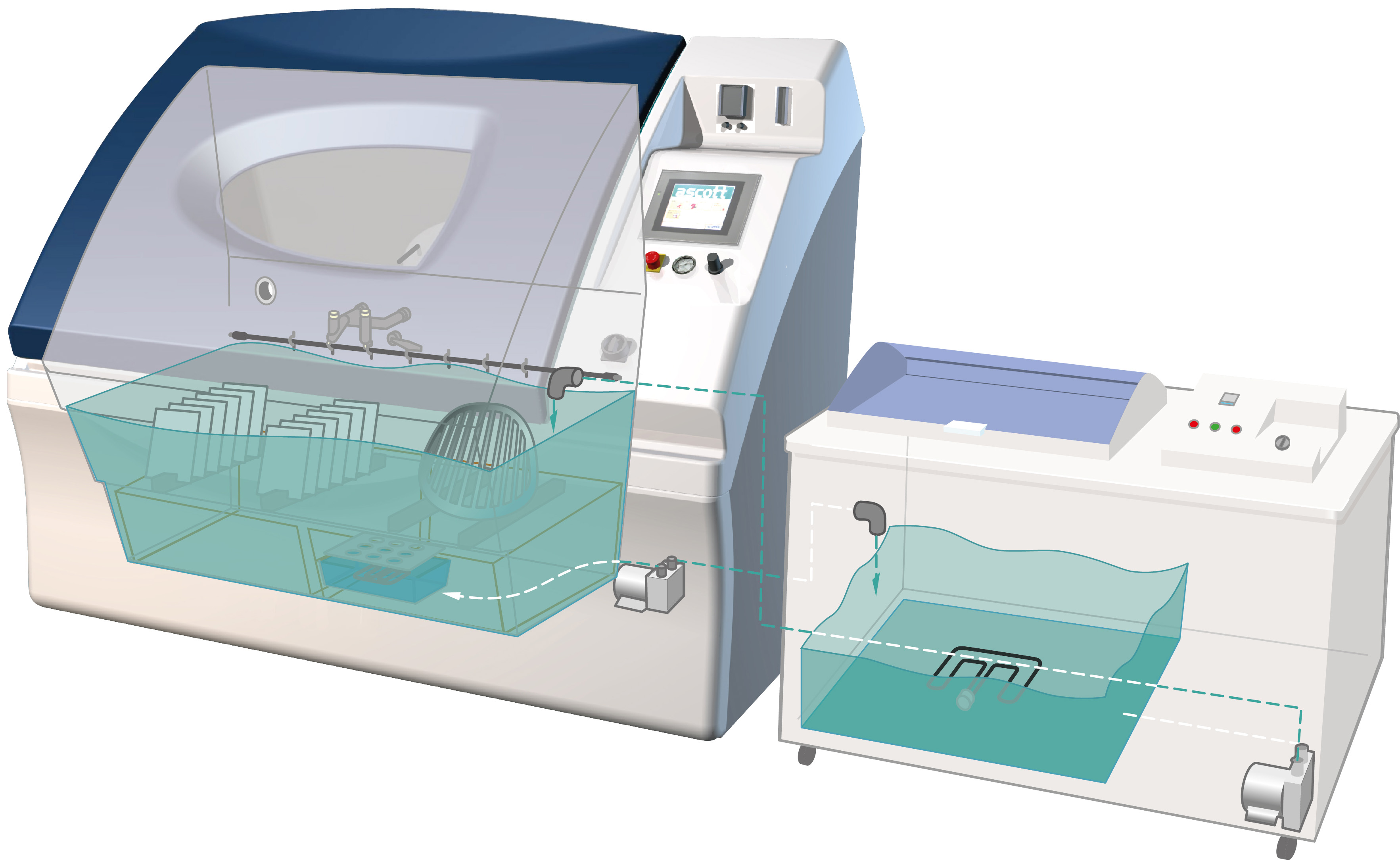

| Liquid Immersion | ACC34 | Under programmed control, heated immersion liquid (usually salt water heated to a user adjustable temperature up to +50°C/+122°F) is automatically pumped from the holding tank into the chamber, immersing the test samples. The liquid is automatically returned to the holding tank at the end of the immersion period. *Exact part number dependent on chamber size. | |

| Liquid Immersion Interface | ACC34/INT | Pre-equips a CCT chamber with everything needed to connect it to an ACC34 liquid immersion facility (available separately). The fitting of this interface enables the liquid immersion facility to be procured at the same time as the chamber, or later if required. *Exact part number dependent on chamber size. | |

| Re-transmission of Temperature & Humidity | ACC36 | Re-transmission of chamber temp & humidity as 2 x 0-10VDC signals via externally mounted socket. For remote data logging. Only available for Premium chambers (iP designations). | |

| Wall wash | ACC42 | A water spray system to automatically wash the internal walls of the chamber with water. Both wash time and duration are user programmable. Requires the chamber to be connected to a continuous pressurised water supply of suitable quality and temperature. Comprises of a water spray system to automatically wash the walls with water for a user adjustable number of minutes, at programmable points within a corrosion test cycle. This test is required for some automotive standards such as Renault D17 2028 or RNES-G-005 or ECC-1. It is also used when rapid cooling is required for JASO M 609 , CCT-1 and other automotive test standards. *Exact part number dependent on chamber size. Note this accessory is fitted as standard with ACC01 ECC1 Kit and all Atmosfar Premium Chambers | |

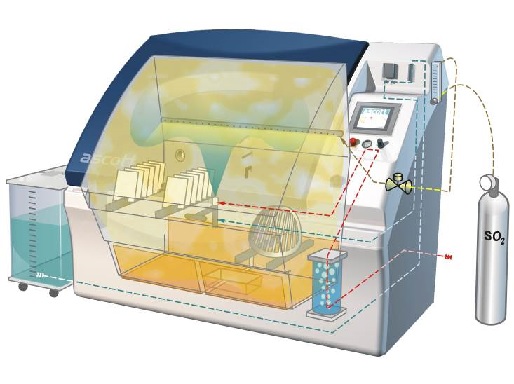

| SO2 Gas Dosing | ACC46 | Designed to meet the requirements of ASTM G85 annex A4, this optional accessory comprises of a chamber mounted dispersion tube, through which SO2 gas is introduced, at a user adjustable rate and for a programmable duration. *Exact part number dependent on chamber size. Only available for Premium chambers (iP designations). Notes. | |

| Temperature data logger | ACC50 | A battery powered, chamber mounted data logger and temperature sensor. Continuously records the chamber air temperature (°C). Logs can be downloaded to a computer running appropriate software (provided). | |

| Chamber Raising Kit | ACC56 | Set of 4 adjustable height legs that allow the chamber to be raised to operate with high level drains. | |

| Manual filling air saturator | ACC66 | Enables the air saturator to be manually filled and periodically topped up with water by hand as an alternative to the automatic fill and top up provided as standard. Adds 75mm/3” to external chamber width. | |

| 80L Salt solution reservoir fitted with low level alarm | ACC59/3 | An 80 Litre (21 US gal) capacity salt solution reservoir, with a graduated scale in litres, a hinging lid for ease of filling and cleaning and mounted on castors for mobility. External Dimensions: 460mm (w) x 620 mm (d) x 675mm (h) Fitted with Low Level Alarm that operates if the salt solution level falls below requirement for approximately 18 hours testing low level alarm at 1-2ml/hour fall-out rates. Sounds audible alarm and displays warning message. If reservoir is not refilled within 18 hours the running chamber program will automatically pause/stop. | |

| Interface for ACC90 | ACC80 | Pre-equips a CCT chamber with everything needed to connect it to an ACC90 dehumidifier (available separately) The fitting of this interface enables the dehumidifier to be procured at the same time as the chamber, or later if required. *Exact part number dependent on chamber size. | |

| Window insulated cover | ACC82 | Comprises of an insulated cover, which is specially shaped to match the window aperture. This will reduce the amount of condensation that can form on the inside of the window during testing and will also improve thermal efficiency. *Exact part number dependent on chamber size. | |

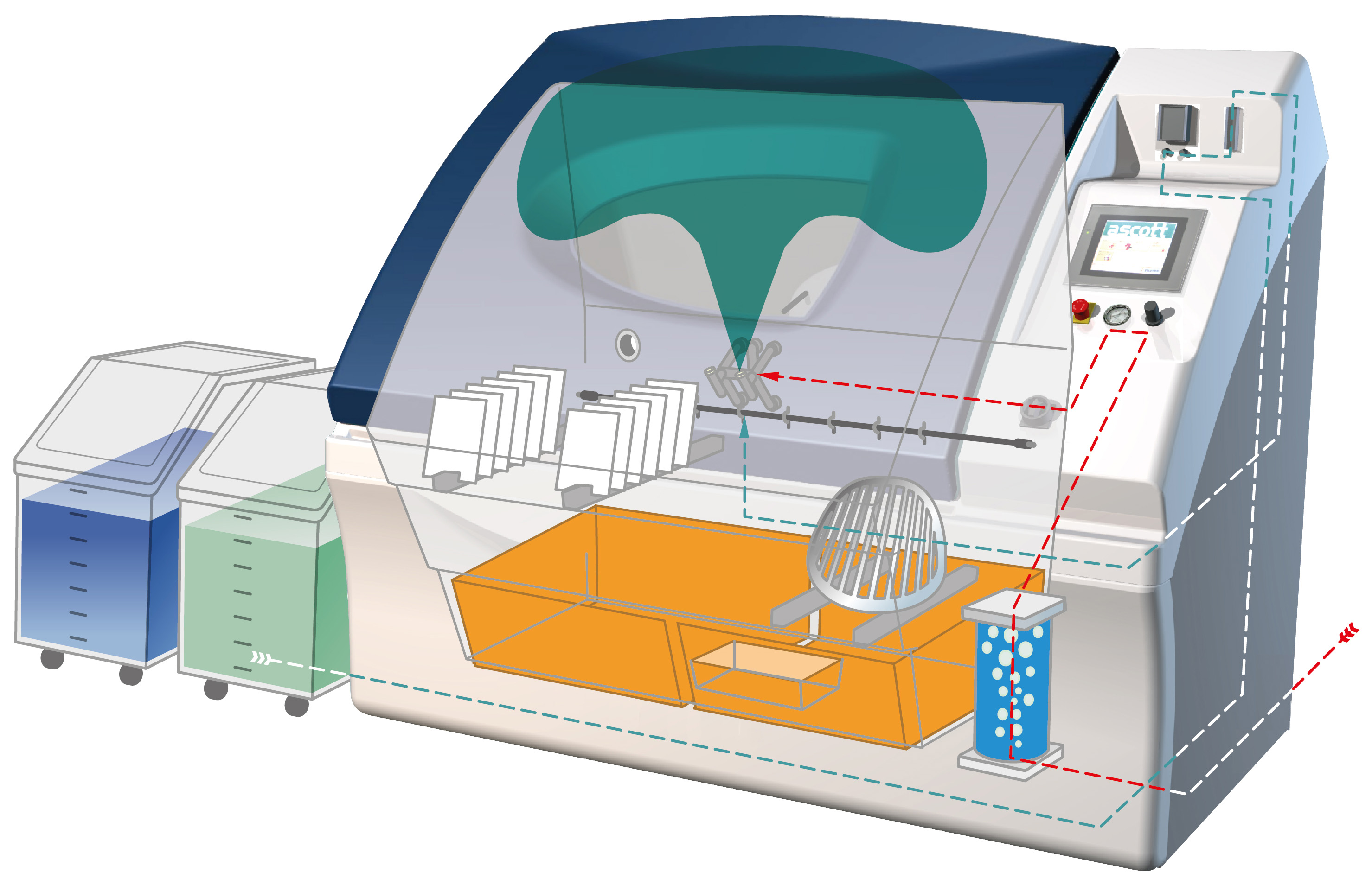

| Multi-solution salt spray | ACC86 | Enables up to three different salt spray climates to be created which can be individually programmed to occur within any test program. Additional salt solution reservoirs, atomizers etc, are included. *Exact part number dependent on chamber size. | |

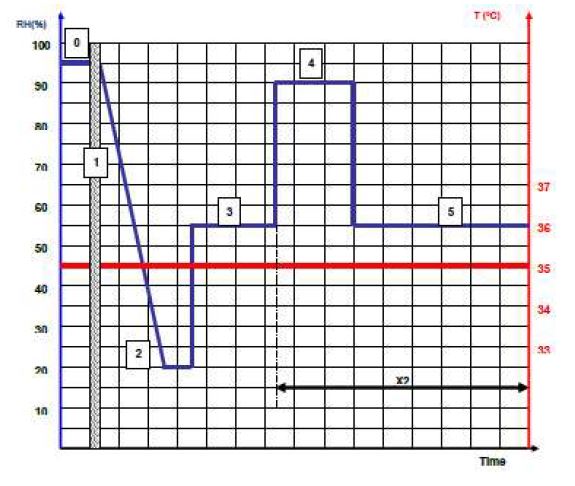

| Dehumidifier | ACC90 | To deliver dehumidified air to CCT chambers where humidity control at, or just below ambient conditions, is required. See graph for range of operation.Note: ACC90 requires the chamber to be pre-equipped with ACC80 interface (available separately). *Exact part number dependent on chamber size. | |

| Exhaust salt scrubber (without circulation Pump) | ACC92/2 | Removes highly corrosive salt fog from the chamber exhaust where it is not convenient or possible to vent to the outside of the building. Removes salt through condensation and by spraying with water. Note: not suitable for use with option ACC46. | |

| Exhaust salt scrubber (with circulation Pump) | ACC92/4 | Removes highly corrosive salt fog from the chamber exhaust where it is not convenient or possible to vent to the outside of the building. Removes salt through condensation and by spraying with water. Note: not suitable for use with option ACC46. | |

| Compressed air coupling | ACC94 | A control panel mounted, quick release coupling to facilitate the connection of a third-party air pressure gauge (not supplied) for checking/calibrating the chamber’s own air pressure gauge. | |

| 80 Litre (21 US gal) capacity salt solution reservoir fitted with Air agitation | ACC59/2 | An 80 Litre (21 US gal) capacity salt solution reservoir, with a graduated scale in litres, a hinging lid for ease of filling and cleaning and mounted on castors for mobility. External Dimensions: 460mm (w) x 620 mm (d) x 675mm (h) Fitted with Air Agitation to assist dissolving salt within a salt solution reservoir to create a thoroughly mixed salt solution. Regulated compressed air supplies a bubbling device that rests in the bottom of the reservoir. Note: requires connection to a compressed air supply. | |

| Atomiser Airflow Optimiser | ACC106 | An anemometer for measuring airflow and a mounting for this which positions it at a fixed distance from the end of the salt spray atomiser. This allows the airflow to be measured and if necessary adjusted. Consistent airflow at the atomiser can be a significant factor in obtaining good salt spray fall-out homogeneity, which is particularly important for some salt spray tests such as Renault ECC-1. | |

| Increased Load Capacity Kit | ACC119 | Mesh racking kit combined with strengthened fibreglass chamber interior to allow greater loads to be tested in the chamber. *Exact part number dependent on chamber size and whether upper or lower racking is required. | |

| Blower Add on Accessory | ACC39 | Addition of a blower fan assembly to assist with quick transitions of temperature/ humidity process values from a high to a lower level, such as GMW 14872. This is achieved by introducing ambient air from the local area in which the equipment is located by means of forced air blower and ball valve, no heat is provided by ACC39. If you required heated air please add ACC47 Note: A variation of ACC39 is already included in ACC80 and ACC01 accessories and is therefore not required. This is also fitted as standard to all Atmosfar Premium chambers | |

| Blower Heater Add On Accessory | ACC47 | Optional accessory to assist quick transitions of increasing and decreasing temperature and also decreasing humidity process values, such as JASO M609 / CCT-1. This is achieved by introducing ambient air from the local area in which the equipment is located by means of a forced air blower and ball valve. An air inlet heater is also fitted and automatically controlled if the chamber temperature needs to be increased, this enables enable a rapid transition from salt spray at 35°C to drying at 70°C within 30 minutes. Note: ACC47 is already fitted as standard with ACC01 & ACC80 accessories, and fitted to all Atmosfar Premium Chamber as standard. | |

| Ford / Volvo / Scania Upgrade kit for CC Chambers | ACC125 | A factory fitted upgrade kit for 450, 1000 and 2000 Litre cyclic (CC) chambers to enable testing to key automotive standards, including; ISO 16701, Ford CETP 00.00-L-467, Volvo VCS 1027,149 (ACT-1), Volvo VCS 1027,1449 (ACT-2), Volvo STD 423-0014, Scania STD4319. | |

| 80L Salt solution reservoir fitted with Air Agitation and low level alarm | ACC59/4 | An 80 Litre (21 US gal) capacity salt solution reservoir, with a graduated scale in litres, a hinging lid for ease of filling and cleaning and mounted on castors for mobility. External Dimensions: 460mm (w) x 620 mm (d) x 675mm (h) Fitted with Low Level Alarm that operates if the salt solution level falls below requirement for approximately 18 hours testing low level alarm at 1-2ml/hour fall-out rates. Sounds audible alarm and displays warning message. If reservoir is not refilled within 18 hours the running chamber program will automatically pause/stop. Also fitted with Air Agitation to assist dissolving salt within a salt solution reservoir to create a thoroughly mixed salt solution. Regulated compressed air supplies a bubbling device that rests in the bottom of the reservoir. Note: requires connection to a compressed air supply. | |

| Salt Solution Reservoir (115 Litres) fitted with Air Agitation | ACC59/6 | A 115 Litre (30US gal) capacity salt solution reservoir, with a graduated scale in litres, a hinging lid for ease of filling and cleaning and mounted on castors for mobility. External Dimensions: 560mm (w) x 620 mm (d) x 675mm (h) Fitted with Air Agitation to assist dissolving salt within a salt solution reservoir to create a thoroughly mixed salt solution. Regulated compressed air supplies a bubbling device that rests in the bottom of the reservoir. Note: requires connection to a compressed air supply. | |

| Salt Solution Reservoir (115 Litres) fitted with Low Level Alarm | ACC59/7 | A 115 Litre (30US gal) capacity salt solution reservoir, with a graduated scale in litres, a hinging lid for ease of filling and cleaning and mounted on castors for mobility. External Dimensions: 560mm (w) x 620 mm (d) x 675mm (h) Fitted with Low Level Alarm that operates if the salt solution level falls below requirement for approximately 18 hours testing low level alarm at 1-2ml/hour fall-out rates. Sounds audible alarm and displays warning message. If reservoir is not refilled within 18 hours the running chamber program will automatically pause/stop. | |

| Salt Solution Reservoir (115 Litres) fitted with Air Agitation & Low Level Alarm | ACC59/8 | A 115 Litre (30US gal) capacity salt solution reservoir, with a graduated scale in litres, a hinging lid for ease of filling and cleaning and mounted on castors for mobility. External Dimensions: 560mm (w) x 620 mm (d) x 675mm (h) Also fitted with Air Agitation to assist dissolving salt within a salt solution reservoir to create a thoroughly mixed salt solution. Regulated compressed air supplies a bubbling device that rests in the bottom of the reservoir. Note: requires connection to a compressed air supply. Fitted with Low Level Alarm that operates if the salt solution level falls below requirement for approximately 18 hours testing low level alarm at 1-2ml/hour fall-out rates. Sounds audible alarm and displays warning message. If reservoir is not refilled within 18 hours the running chamber program will automatically pause/stop. | |

| Salt Solution Reservoir (160 Litres) with Air Agitation | ACC59/10 | A 160 Litre (42.2 US Gal) capacity salt solution reservoir, with a graduated scale in litres, a hinging lid for ease of filling and cleaning and mounted on castors for mobility. External Dimensions: 840mm (w) x 500mm (d) x 790mm (h) Also fitted with Air Agitation to assist dissolving salt within a salt solution reservoir to create a thoroughly mixed salt solution. Regulated compressed air supplies a bubbling device that rests in the bottom of the reservoir. Note: requires connection to a compressed air supply. | |

| Salt Solution Reservoir (160 Litres) with Low level Alarm | ACC59/11 | A 160 Litre (42.2 US Gal) capacity salt solution reservoir, with a graduated scale in litres, a hinging lid for ease of filling and cleaning and mounted on castors for mobility. External Dimensions: 840mm (w) x 500mm (d) x 790mm (h) Fitted with Low Level Alarm that operates if the salt solution level falls below requirement for approximately 18 hours testing low level alarm at 1-2ml/hour fall-out rates. Sounds audible alarm and displays warning message. If reservoir is not refilled within 18 hours the running chamber program will automatically pause/stop. | |

| Salt Solution Reservoir (160 Litres) with Air Agitation and Low level Alarm | ACC59/12 | A 160 Litre (42.2 US Gal) capacity salt solution reservoir, with a graduated scale in litres, a hinging lid for ease of filling and cleaning and mounted on castors for mobility. External Dimensions: 840mm (w) x 500mm (d) x 790mm (h) Also fitted with Air Agitation to assist dissolving salt within a salt solution reservoir to create a thoroughly mixed salt solution. Regulated compressed air supplies a bubbling device that rests in the bottom of the reservoir. Note: requires connection to a compressed air supply. Fitted with Low Level Alarm that operates if the salt solution level falls below requirement for approximately 18 hours testing low level alarm at 1-2ml/hour fall-out rates. Sounds audible alarm and displays warning message. If reservoir is not refilled within 18 hours the running chamber program will automatically pause/stop. | |

| Salt Solution Reservoir (90 Litres) | ACC59/13 | A 90 Litre (23US gal) capacity external salt solution reservoir & removable lid for ease of filling and cleaning. Graduated scale in litres. Can be mobile and mounted on castors for mobility when purchased with ACC59/15 Salt Solution Reservoir Dolly. External Dimensions: 540mm/21″ x 635mm /25″ width x height | |

| Salt Solution Reservoir (73 Litres) | ACC59/14 | A 73Litre (19 US gal) capacity External salt solution reservoir & lid for ease of filling and cleaning. Graduated scale in litres. Can be mobile and mounted on castors for mobility when purchased with ACC59/15 Salt Soution Reservoir Dolly. External Dimensions: 425mm Dia x 630mm (h) | |

| Salt Solution Reservoir (73-90L) Dolly | ACC59/15 | A Dolly for 73Litre (19 US gal) and 90L (23 US gal) External salt solution reservoir & lid for mobility. | |

| CC450IP Installation Kit | ACC58/5 | A Handy Installation kit for CC450iP Chambers to help you connect your chamber to your services and exhaust. Saves you time resourcing them locally and ensuring you get everything you will need. 3m of 3/4″ Drain Pipe inc couplers and elbows 3m of 4″ Exhaust Pipework inc Couplers and Elbows 6m of 13mm Braided hose inc Clips for Air and Water connections 1/2″ Hosetail Coupler-1/4″ Male-8mm to allow a push fitting. (Items can be purchased separately too upon request). | |

| CC1000/1300IP Installation Kit | ACC58/8 | A Handy Installation kit for CC1000/1300iP Chambers to help you connect your chamber to your services and exhaust. Saves you time resourcing them locally and ensuring you get everything you will need. Comprising of: 3m of 3/4″ Drain Pipe inc couplers and elbows 3m of 4″ Exhaust Pipework inc Couplers and Elbows 6m of 13mm Braided hose inc Clips for Air and Water connections 1/2″ Hosetail Coupler-1/4″ Male-8mm to allow a push fitting. (Items can be purchased separately too upon request). | |

| CC2000/2600iP Installation Kit | ACC58/11 | A Handy Installation kit for CC2000/2600iP Chambers to help you connect your equipment to your services and exhaust. Saves you time resourcing them locally and ensuring you get everything you will need. 3m of 3/4″ Drain Pipe inc couplers and elbows 3m of 4″ Exhaust Pipework inc Couplers and Elbows 6m of 13mm Braided hose inc Clips for Air and Water connections 1/2″ Hosetail Coupler-1/4″ Male-8mm to allow a push fitting. (Items can be purchased separately too upon request). | |

| CR4 Grade Steel Corrosion Test Panels for ISO 9227 & VDA 233-102 | ACC131 | Ascott CR4 Test Panels are used to check the reproducibility and repeatability of the test results for Salt Spray or Cyclic Corrosion Test Chambers being being used to run ISO 9227 or VDA 233-102 Click here to purchase CR4 Test Panels from Ascott online. | |

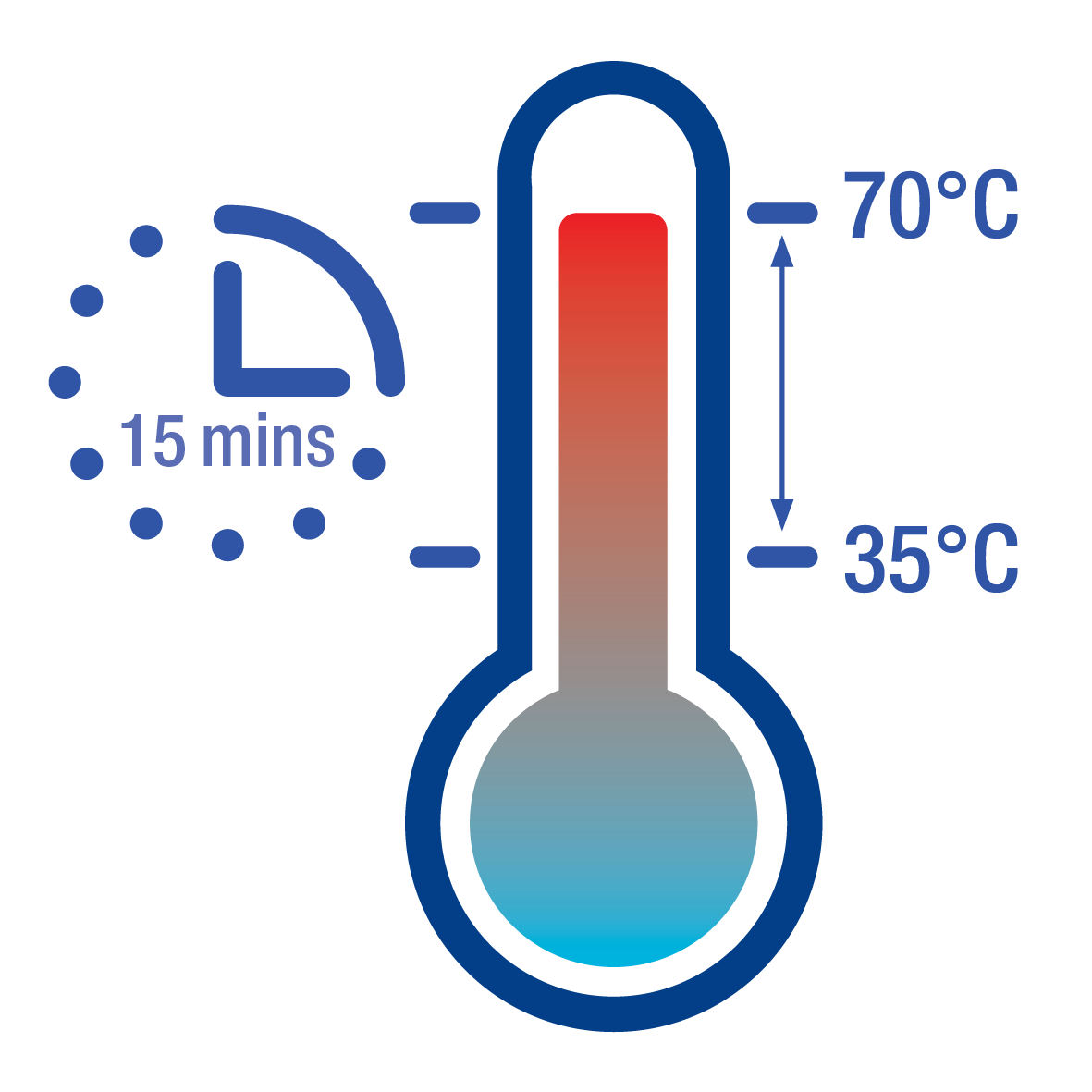

| Ultra Rapid Ramping Heater System to 80°C | ACC47/8 TO ACC47/15 | A further upgrade to the heating system of the chamber allows the temperature to transition between 35°C and 70°C within 15minutes, required for Hyundai CCT-A / Hyundai CCT-B, and to also achieve a maximum operating temperature of 80°C, required for Volkswagen PV1200 & PV1209. Note: ACC47 is already fitted to all Atmosfar Premium Chamber as standard. | |

| Two Button Canopy Control | ACC07 | Two button canopy operation ensures that the user must stand to the side of the chamber and use both hands in order to operate the pneumatically actuated canopy | |

| Test Plate to hold small items/fasteners | ACC43 | A polycarbonate test plate holder pre-drilled with 7 holes (3 x 6mm, 2 x 5mm, 2 x 4mm) which are fitted with the nuts and bolts:

When loaded with samples the plate slots into the standard slotted sample racks (Ref ACC16) The plate can be used in different ways, if the nuts and bolts are removed the holes can be used to suspend samples directly (as long as the samples do not fall through the hole), or small samples with a through hole (nuts, washers etc.) can be suspended on the bolts. | |

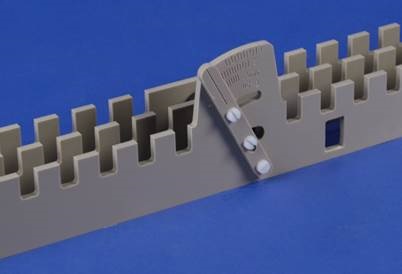

| Sikkens® Scratch Tool | ACC49 | This scratching tool is specially designed to perform scribes on coated steel panels or test substrates prior to salt spray testing for example as described in ISO 9227 & ISO 12944-6 As standard, the scratch tool is supplied with 3 tungsten carbide cutting blades;

The blade is positioned by an adjustable guide block to assist cutting a straight line. The guide block can be easily adjusted using the Allen keys provided. The tool features a soft grip ergonomically designed handle for ease of use and is supplied in a carry case. | |

| User programmable output signal | ACC78 | This option enables the chamber user to have their own remote electrical equipment switched on/off at user programmable times, during a running test program. The output is provided via a voltage free change over contact (3A rated at 30VDC/250VAC) terminated at a chamber mounted 3-pin plug and socket for the user to wire to. There are 10 user settable time events, up to a maximum time of 9999 hours and 59 minutes. Maximum of 4 can be fitted to a chamber | |

| Salt Solution Reservoir (227 Litres) | ACC59/16 | A 227 Litre (59.9 US Gal) salt solution reservoir, with a graduated scale in litres, a hinging lid for ease of filling and cleaning and mounted on castors for mobility. External Dimensions: 830mm x 640mm x 740mm | |

| Salt Solution Reservoir (227 Litres) fitted with Air Agitation | ACC59/17 | A 227 Litre (59.9 US Gal) salt solution reservoir, with a graduated scale in litres, a hinging lid for ease of filling and cleaning and mounted on castors for mobility. External Dimensions: 830mm x 640mm x 740mm Also fitted with Air Agitation to assist dissolving salt within a salt solution reservoir to create a thoroughly mixed salt solution. Regulated compressed air supplies a bubbling device that rests in the bottom of the reservoir. Note: requires connection to a compressed air supply. | |

| Salt Solution Reservoir (227 Litres) fitted with Low Level Alarm | ACC59/18 | A 227 Litre (59.9 US Gal) salt solution reservoir, with a graduated scale in litres, a hinging lid for ease of filling and cleaning and mounted on castors for mobility. External Dimensions: 830mm x 640mm x 740mm Fitted with Low Level Alarm that operates if the salt solution level falls below requirement for approximately 18 hours testing low level alarm at 1-2ml/hour fall-out rates. Sounds audible alarm and displays warning message. If reservoir is not refilled within 18 hours the running chamber program will automatically pause/stop. | |

| Salt Solution Reservoir (227 Litres) fitted with Air Agitation & Low Level Alarm | ACC59/19 | A 227 Litre (59.9 US Gal) salt solution reservoir, with a graduated scale in litres, a hinging lid for ease of filling and cleaning and mounted on castors for mobility. External Dimensions: 830mm x 640mm x 740mm Also fitted with Air Agitation to assist dissolving salt within a salt solution reservoir to create a thoroughly mixed salt solution. Regulated compressed air supplies a bubbling device that rests in the bottom of the reservoir. Note: requires connection to a compressed air supply. Fitted with Low Level Alarm that operates if the salt solution level falls below requirement for approximately 18 hours testing low level alarm at 1-2ml/hour fall-out rates. Sounds audible alarm and displays warning message. If reservoir is not refilled within 18 hours the running chamber program will automatically pause/stop. |