Atmosfär Chambers – Key Features

Atmosfär chambers have been specifically designed for fully automatic testing in accordance with highly demanding laboratory-accelerated corrosion tests which have become increasingly popular in some sectors of the automotive industry.

These tests are cyclic in nature and comprise of exposure under controlled and varying conditions of temperature and humidity, with intermittent spraying of a salt solution directly on to the samples under test, from a high level swaying spray bar.

Popular Atmosfar Test Standards:

- FORD CETP00.00-L-467

- ISO 16701

- Scania STD 4319

- Scania STD 4445

- TPJLR.52.265

- Volvo STD 1027,1375

- Volvo STD 1027,14

- Volvo STD 423-0014

- Volvo STD 4233

Two model sizes:

- 1300 Ltr (45.9 cu ft)

- 2600 Ltr (91.8 cu ft)

Extensive optional testing facilities:

Extensive range of optional testing facilities, such as SO2 gas dosing and liquid immersion. – Click to see the optional accessories available

The chamber can be selected with one of three different cooling options

- Lite Version down to 20°C / 68°F

- Sub Zero version down to -20°C / -4°F

- Sub Zero version down to -40°C / -40°F

- Now also available with CO2 Cooling according to EU F-GAS regulation 2024/573

- Water cooling options are available for the sub zero options if heat dissipation is an issue where the chamber is installed.

All Ascott Atmosfär Corrosion Test chambers feature:

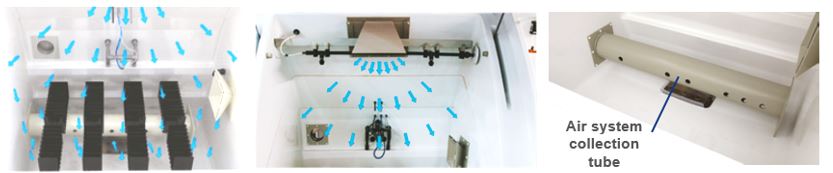

- Oscillating spray bar with magnetically coupled drive system, for compliance with the most demanding automotive test standards.

- Integrated air conditioning unit, to achieve demanding temperature and humidity combinations.

- Psychrometric humidity control module, for more exacting control of humidity, especially at levels around 95% RH.

- An option of different cooling units from Ambient control (Lite Model) to sub zero at -20 or -40 degrees C. Water cooled options are also available for sub cooling units where room heat dissipation is an issue.

- Now also available with CO2 Cooling according to EU F-GAS regulation 2024/573

Plus the features of Ascott CCT corrosion test chambers:

- Ergonomic design low loading threshold for easy loading and unloading.

- ‘Easy Open’ pneumatically operated canopy.

- Dry seal gasket prevents wetting operator’s clothes, etc.

IP Connectivity - External large capacity salt solution reservoirs for ease of cleaning.

- Calibration certificate.

- Canopy colour choice.

- Interior viewing window. (Lite versions only)

- Consumables spares kit.

- Easily accessible salt spray atomizer(s) in transparent hard-wearing acrylic.

- Purge of the cabinet interior with fresh air after testing and before the chamber is opened.

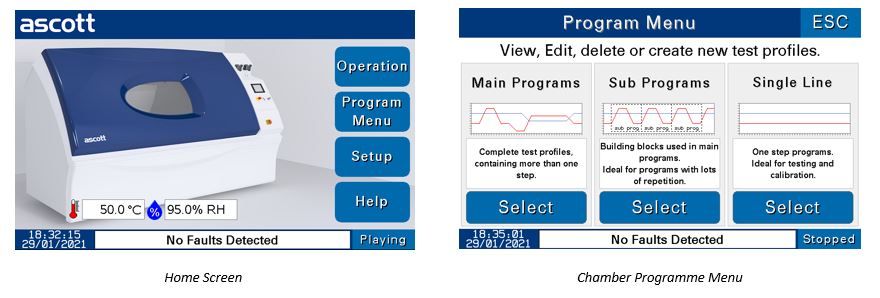

- 7’’ ‘touch’ activated screen, with a 480p (0.38 megapixel) high resolution display, and a ‘menu’ driven icon based commands, available in multiple languages for ease of understanding and use.

- Temperature and Humidity monitoring in SCADA using OPC-UA. (Open Platform Communications United Architecture)

- Large capacity memory, allowing for extensive customer programmes to be stored, 254 main programmes of up to 200 steps, 100 sub programmes and 254 single line programmes.

- RJ45 communications port for connection to a local area network (LAN) for logging and remote programming via a computer running optional Ascott software (ACC121)

- A real-time, user configurable ‘clock’ to enable different test samples to be batched and have their exposure time monitored separately, with alarms to warn when a pre-set test period has been completed.

- External portable salt solution tanks for ease of cleaning – One at 90L and one at 160L.

For further information contact us on the form below, alternatively, to speak with one of our sales representatives call us on +44 (0) 1827 318040