Ascott – At the forefront of chamber design

About Ascott Analytical Equipment

With over 35 years of specialist experience, Ascott Analytical Equipment has established itself as a global leader in the design and manufacture of corrosion test cabinets. From our headquarters in Tamworth, UK, where all our cabinets are built, we export worldwide and have earned multiple awards for export excellence.

We focus exclusively on corrosion testing — it’s all we do — which gives us a level of expertise and technical depth unmatched by generalist manufacturers. Our product range includes salt spray cabinets and cyclic corrosion chambers, trusted by customers in a wide range of industries where precision, compliance, and repeatability are critical.

Our latest cabinet range is the result of customer-led innovation, engineered to meet the increasing demands of modern corrosion testing. With evolving materials, advanced coatings, and rising performance expectations, accurate climate control and test replication have never been more important — and that’s where Ascott excels.

Each chamber is built to order and fully customisable, supported by a global network of partners providing ongoing after-sales support and service. A comprehensive selection of accessories and options ensures your solution fits your specific testing requirements.

At Ascott, we’re committed to delivering world-class performance and exceptional value. If you’re seeking a reliable, high-performance solution for corrosion testing, get in touch with us today — and let our expertise become your advantage.

Salt Spray Corrosion Test Chambers

Salt Spray Corrosion Test Chambers

Salt Spray Testing: A Proven Standard for Corrosion Resistance

The salt spray test—also known as salt fog or salt mist testing—has been a benchmark method for evaluating corrosion resistance across a wide range of industries for decades. Backed by an extensive history, a wealth of test data, and numerous international corrosion testing standards (such as ASTM B117 and ISO 9227), it remains one of the most widely used accelerated corrosion tests today.

This test offers a quick and reliable way to assess corrosion performance, making it ideal for comparing protective coatings, surface treatments, or material quality. Its primary application is in production quality control, where it is used to audit the effectiveness of manufacturing processes and ensure products meet corrosion resistance expectations.

For more information on Salt Spray chambers

Cyclic Corrosion Test (CCT) Chambers

Cyclic Corrosion Test (CCT) Chambers

Cyclic Corrosion Testing (CCT): Simulating Real-World Corrosive Environments

Cyclic Corrosion Testing (CCT) is an advanced method of accelerated corrosion testing that simulates a range of real-world environmental conditions within a controlled corrosion test chamber. By replicating cycles of salt spray, drying, humidity, and temperature variations, CCT provides a more accurate prediction of a material or component’s long-term durability and life expectancy under actual service conditions.

Widely adopted across industries, CCT is especially prominent in the automotive sector, where many manufacturers have developed their own Cyclic Corrosion Test standards to ensure the performance and reliability of coatings, surface treatments, and materials exposed to harsh environments.

For more information on Cyclic Corrosion chambers

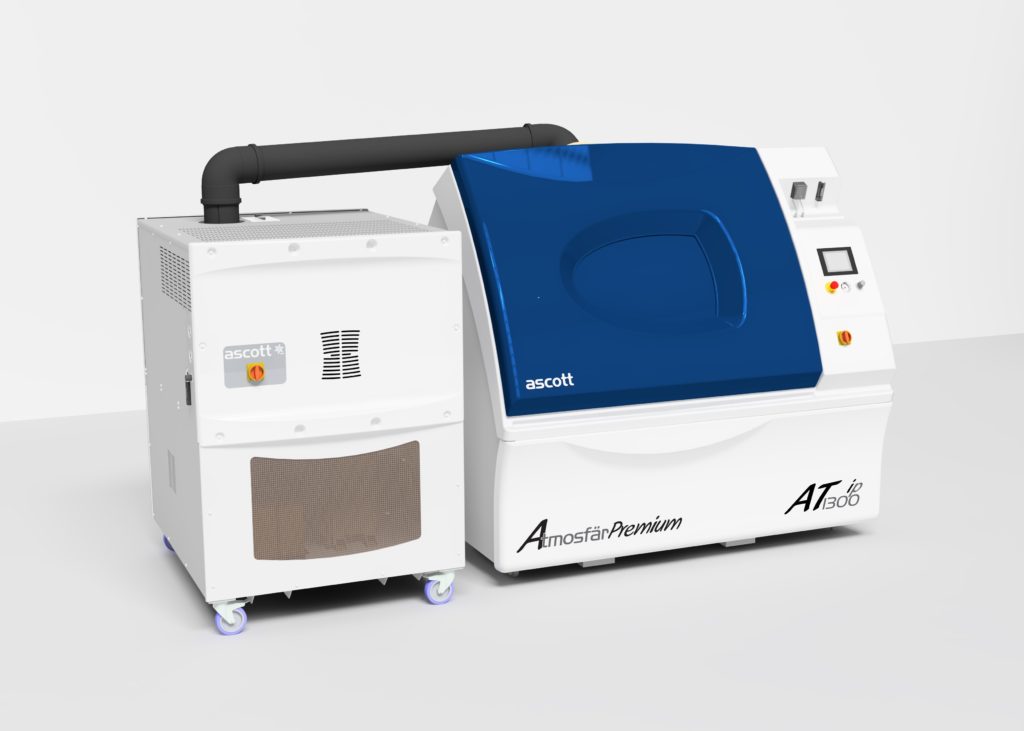

Atmosfär Corrosion Test Chambers for Automotive CCT Standards

The Atmosfär Corrosion Test Chamber is a specialized version of the Ascott CCT (Cyclic Corrosion Test) chamber, engineered to meet the stringent automotive corrosion testing requirements of manufacturers like Ford and Volvo. Designed for advanced cyclic corrosion testing, the Atmosfär includes several enhanced features for greater test accuracy and repeatability.

Key capabilities include a high-level swaying salt spray bar for uniform salt fog application, vertical high-velocity air drying, refrigerated dehumidification, and a psychrometric humidity measurement system—all of which enable compliance with specific automotive CCT standards and provide reliable, real-world simulation of harsh environmental conditions.

For more information on Atmosfär chambers

Kesternich SO2 Humidity Test Chambers for Acidic Corrosion Testing

The Kesternich test, widely used in corrosion testing, simulates the effects of acidic rain by combining humidity with sulfur dioxide (SO2) in a controlled environment. Our Kesternich SO2 Humidity Test Chamber offers a capacity of 300L and is designed to replicate corrosive conditions that materials and coatings may face in real-world industrial atmospheres.

This corrosion test method is governed by international standards including DIN EN ISO 6988, DIN 50018, ASTM G87, ISO 3231, and ISO 22479. The chamber functions as a condensate humidity chamber, an SO2 chamber, or an SO2 humidity chamber depending on your testing needs. For user safety, the canopy is hermetically sealed and pneumatically secured during operation.

For more information on Kesternich chambers

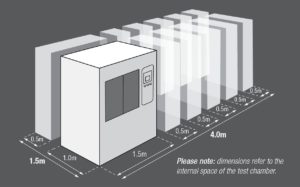

CorroFlex custom size Test Chambers

Ascotts latest innovative product range is the CorroFlex range of salt spray or cyclic corrosion test chambers, which are custom built to your requirements and size. The CorroFlex chambers can be up-to 4m /157” internal width and either 1m/40″ or 1.5m/60” internal depth (contact us for any sizes outside of this range) and with a weight capacity upto 500kg /1100lbs as standard.

Click here for the latest CorroFlex brochure

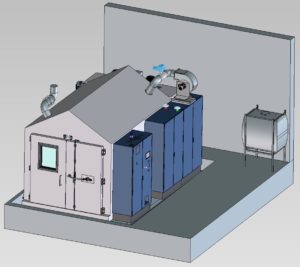

Walk in / Drive in Corrosion Rooms

Ascott was recently acquired by Weiss Technik GmbH, world market leader for environmental simulation systems. As a part of this acquisition Ascott can now offer Walk in / Drive in Corrosion rooms manufactured by Weiss Technik, for testing large items such a EV Battery packs or complete vehicles. With the joint expertise of Weiss Technik and Ascott Analytical you can rest assured your testing will remain compliant and repeatable. If you would like a quote for a walk in corrosion room please get in touch